|

|

Biomaterials Tutorial

Surface Plasmon Resonance (SPR)

Janet Cuy

University of Washington

Engineered Biomaterials

Surface plasmon resonance (SPR) is a non-destructive analysis

technique, useful for investigating thin layers of molecules upon a

material surface. Specifically, SPR is capable of detecting changes

in refractive index (n) occurring near the surface of a metal

(within ~200nm) [1]. Refractive index refers to the speed with which

light passes through a material compared to the speed with which it passes

through air. For example, light travels more slowly through glass

than it does through air, therefore glass has a higher refractive index

than air (nglass=1.5-1.6, nair=1) [2].

The use of a metal sensing surface in SPR is critical, as this

technique capitalizes upon the fact that metals (like other electrically

conductive materials) contain electrons that behave as a continuous "sea"

of charge. This "sea" of charge can undergo charge-density

oscillations (or plasmons) at the surface of the conductor, particularly

at a surface in contact with an insulator [3, 4, 5]. Following the

"sea" analogy, imagine the behavior of seaweed washing up against a shore:

the density of seaweed (i.e., electrons) at the shore (the

interface between the "conducting" water and the "insulating" sand) varies

with the ebb and flow of the tide (the plasmon).

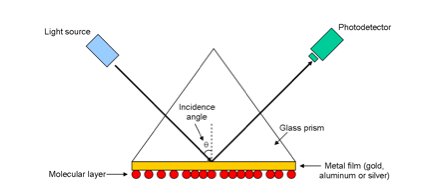

A simple SPR instrument set-up generally consists of a light source, a

glass prism with a high refractive index n, a thin (50 nm) metal

film placed in contact with the bottom of the prism and a photodetector

(see Figure 1) [6]. The molecular layer of interest can be coated

onto the thin metal film may be coated with a molecular layer of interest

on the side opposite the prism.

Figure 1. Basic SPR instrument configuration. Adapted from

Levesque and Paton [6].

Surface plasmon waves (SPWs) can be generated at the interface between

the conductive metal film and the insulating molecular layer by striking

the metal sensor with a particular type of light [7, 8]. At the same

time that SPWs are generated, light is also reflected off of the metal

surface. Past a specific incident angle (q in Figure 1), and only in

the presence of the highly refractive glass prism, all the energy from the

incident light wave will be transferred to the reflected light wave (total

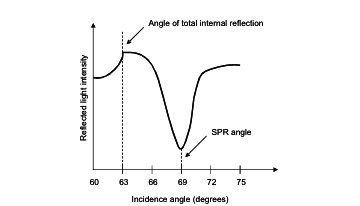

internal reflection) [9]. However, at a very specific angle

past the point of total internal reflection (the SPR angle), a majority of

the incident light energy that would have typically been transferred to

the reflected light wave will instead interact with the generated SPWs,

resulting in a phenomenon called resonance [6, 10]. At resonance, a

minimum in reflected light intensity will be observed, and the SPR angle

can thus be determined by measuring the intensity of the reflected light

(via photodetector), and plotting it as a function of incidence angle (see

Figure 2) [10].

Figure 2. Example of SPR spectrum. Adapted from

Kolomenskii, et al. [11].

The SPR angle is dependent on several factors, including:

characteristics of the metal film, the incident light, and the thickness

and refractive index of the molecular layer in contact with the metal

sensing surface [10]. Consequently, spectra can be generated for a

metal surface with and without a coated molecular layer. Then, the shift

in SPR angle between the two can be quantified and used to calculate the

thickness or refractive index of the adhered molecules [12]. SPR has

proven useful in determining both growth in the thickness of a molecular

layer [13] and loss in thickness, even of a single monolayer [14].

Along with its ability to determine the thickness of coated films, SPR

has also emerged as a technology in the area of sensors (e.g.,

for the detection of physical quantities, chemicals and biologics)

[8]. Physical quantities (such as temperature and humidity) can be

deduced from changes in refractive index. Chemical sensing can use

changes in refractive index to indicate changing concentrations of

molecules adhered to the metal surface (as a result of chemical

reactions). Biosensing can also use refractive index changes to

deduce the occurrence of binding interactions (such as between antigens

and antibodies). SPR also provides the important advantage of being

able to monitor reactions in real-time, without the need to go through the

often complicated process of labeling molecules with fluorescent or

radioactive probes [15].

Like all surface analysis techniques, SPR has its limitations in terms

of sensitivity (the smallest amount of molecule detectable) [5, 8],

resolution (the smallest difference in SPR angle distinguishable) [8, 16]

and sample characteristics (geometry, thickness, etc.). However,

this technique still provides a remarkable variety of capabilities for the

characterization of reaction kinetics and thin film properties, with a

high degree of sensitivity and in real-time—all important factors for a

biomaterials scientist involved in the engineering, alteration and study

of functionalized surfaces.

References:

- Sigal GB, Mrksich M, Whitesides GM. Using surface plasmon resonance

spectroscopy to measure the association of detergents with

self-assembled monolayers of hexadecanethiolate on gold. Langmuir 1997;

13: 2749-2755.

- Foster B. Optimizing light microscopy for biological and clinical

laboratories. Dubuque: Kendall/Hunt; 1997. p. 5.

- Raether H. Surface plasma oscillations and their applications. Phys

Thin Films 1977; 9: 145-244.

- Ratner BD, Castner DG. Electron spectroscopy for chemical analysis.

In: Vickerman JC, editor. Surface analysis: The principal techniques.

New York: John Wiley&Sons, 1997.

- Garland PB. Optical evanescent wave methods for the study of

biomolecular interactions. Q Rev Biophys 1996; 29: 91-117.

- Levesque L, Paton BE. Detection of defects in multiple-layer

structures by using surface plasmon resonance. Appl Opt 1997; 36:

7199-7203.

- Caruso F, Jory MJ, Bradberry GW, Sambles JR, Furlong DN.

Acousto-optic surface-plasmon resonance measurements of thin films on

gold. J Appl Phys 1998; 83: 1023-1028.

- Homola J, Yee SS, Gauglitz G. Surface plasmon resonance sensors:

Review. Sensors Actuators B:Chem 1999; 54: 3-15.

- Fishbane PM, Gasiorowicz S, Thornton ST. Physics for scientists and

engineers. Englewood Cliffs: Prentice Hall, 1993.

- Stenberg E, Persson B, Roos H, Urbaniczky C. Quantitative

determination of surface concentration of protein with surface plasmon

resonance using radiolabeled proteins. J Colloid Interface Sci 1991;

143: 513-526.

- Kolomenskii AA, Gershon PD, Schuessler HA. Sensitivity and detection

limit of concentration and adsorption measurements by laser-induced

surface-plasmon resonance. Appl Opt 1997; 36: 6539-6547.

- de Bruijn HE, Kooyman RPH, Greve J. Determination of dielectric

permittivity and thickness of a metal layer from a surface plasmon

resonance experiment. Appl Opt 1990; 29: 1974-1978.

- Caruso F, Niikura K, Furlong DN, Okahata Y. Ultrathin multilayer

polyelectrolyte films on gold: construction and thickness determination.

Langmuir 1997; 13: 3422-3426.

- Herminghaus S, Leiderer P. Nanosecond time-resolved study of pulsed

laser ablation in the monolayer regime. Appl Phys Lett 1991; 58:

352-354.

- Geddes NJ, Martin AS, Caruso F, Urquhart RS, Furlong DN, Sambles JR

et al.Immobilisation of IgG onto gold surfaces and its

interaction with anti-IgG studied by surface plasmon resonance. J

Immunol Methods 1994; 175: 149-160.

- Tao NJ, Boussaad S, Huang WL, Arechabaleta RA, D'Agnese J. High

resolution surface plasmon resonance spectroscopy. Rev Sci Instrum 1999;

70: 4656-4660.

|

|